My Agate Workshop

My agate workshop, the story of a challange

May be it is not believable, but after 24 years, cutting and polishing agates still remains as a real challenge for me. Because of agate collecting has not found its real situation as a regular hobby, the routine cutting and polishing implements, like those produce by Lorton or Raytech companies could not be found in instrument shops in Iran.

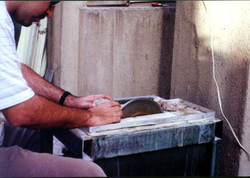

But I could not wait for a miracle! Thus decided to make whatever I need for arranging a complete agate cutting and polishing workshop. In this way, at first I counted on my technical skin and the second on my books and other friends in the agate world. “Gem Cutting” book written by John Sinkankas heartened me to test my skill in making a simple 25 cm diameter diamond saw, cutting machine. It still works as well as the first day! Fast and working, but I could not make an accurate clasp for it as commercial sawing machines. It is very important, because I push agates toward the blade saw by hand, and even little movements of sample against the saw produce a bumpy surface after cutting. This bumpy surface of cut agate samples in any sizes trouble me during lapping. It takes a long time that such a grooved surface becomes flat and smooth. Also making slabs from agates are not easy in this way.

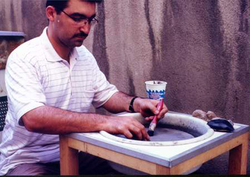

Then I made a 30 cm diameter which works with different sizes of emery and carborandum powders. It could be changed and equipped with a leather buff for polishing stage.

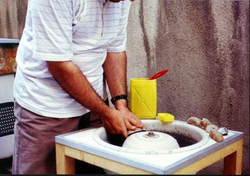

Next step was turning an old juicer to a fast polishing machine. I equipped it with a 22.5cm diameter soft iron lap so that I could stick wet & dry sandpapers and leather sheets on it. It came through innovation and effort, works effective, but only on little nodules. Lapping was still the most suitable machine for larger agates, but wasted time and powders in proportion.

The number of Iranian agates in my collection grew up and lapping of them was still the main problem. This time my dear friend Robert M.B de Jager from the Netherland helped me to design and make a vibratory lapping machine by analyzing his commercial vibro-lap and sending me numbers of accurate photos. Then I succeeded to make a vibratory lapping machine, while I had never seen this machine from close. It helps me to save my time and polish a number of agates together, but because of bumpy surface it still takes a long time.

There are a few of my students in the university those are interested in agate collecting with me. They cut and polish a part of my agates in the petrography thin section making workshop. There are a 20cm diamond saw cutting machine and a twin lapping machine which works both with wet grinding powders and dry sand papers. Also here, lake of clasp in sawing machine bring bumpy surface problem along and we waste many time for reaching to a good polished surface.

"Click on photos for seeing more details in larger size"